Resin Coated Sand Manufacturer with capacity of 50000 MT per annum

Call us 9:00am - 6:00pm

+91 9922930766

E-mail us

mktg@samarthsand.com

Tailor made solutions to Veining defect

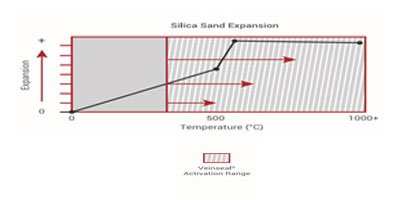

Casting defects such as veining and sand fusion cause considerable losses and costs for any foundry. These defects primarily originate from sand expansion behavior of core and moulds.

To counter the expansion behavior of moulds and cores, Samarth Group provides tailor made grades of Antiveining compounds and Samarth Coated Sand grades having antiveining behavior. Foundries benefit from these product to eliminate/reduce considerably such defects which help foundries optimize the process cost, avoid delay in fettling and also reduce inventories in finishing stage.

Through the Trading division of Samarth Foundry Services Pvt Ltd, we supply ‘Veinseal’- Anti-veining compound manufactured by global leader in this market, Prince Minerals LLC (USA). Prince Minerals is a multinational corporation that produces a range of premium quality foundry supplies for various critical applications. Samarth Foundry Services is an authorized distributor of Prince Minerals for Veinseal and few other products.

Distributor of Prince Minerals LLC, USA, for Antiveining Compound

VEINSEAL : GLOBAL INNOVATION, LOCALLY DELIVERD

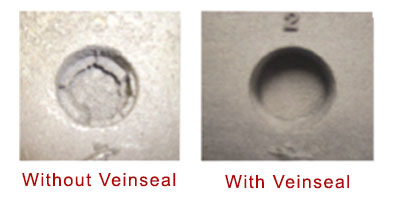

Veinseal™ is an antiveining compound for use in gray and ductile iron castings. When mixed with foundry sand and resin to form the core, Veinseal™ prevents thermal deformation or cracking of the silica. Two other Veinseal™ formulations are also available to improve surface finish and to prevent penetration.

VEINSEAL CASTING DEFECT SOLUTIONS

STOP DEFECTS: Casting defects such as veining and burn-ins cause considerable losses and costs for any foundry .The negative effects of these defects can include

- Increased rate of scrapped castings and necessary rework.

- Increased process costs and prolonged manufacturing cycles

- Failure to meet customer’s quality expectation

VEINSEAL CASTING DEFECT SOLUTIONS

Veinseal is an engineered sand additive. It is a unique blend of superior quality. Materials specifically designed to improve your casting process. It effectively prevents veining and other casting defects.

Our technology advanced formulations, designed for steel and iron applications are engineered to eliminate casting defects caused by the thermal expansion of chemically.

Veinseal®, an antiveining agent is a unique blend of superior quality materials specifically designed to improve the quality of your casting.

Veinseal Antiveining Compound Benefits

- CONTROL sand Expansion

- EASY Incorporation into your sand core Mixing process

- IMPROVE Overall Casting Quality

- MAINTAIN High Tensile Strength

- PREVENT Veining & Gas Defects

- REDUCE Processing Times & Scrap Rates

- SAVE on Machining Labor & Tool Costs

- Virtually NO LOI with Inorganic Formulations

Inorganic & Organic Formulations Available.

Case Studies

Veining Defect :

Heavy veining at inner pockets.

Unable to remove in fettling process.

Result is rejection of casting.

Cost of poor quality approximately is 2.50 lac.

After Veinseal™ Solution :

Veining reduced by 95% in single trial.

Major saving in cost of poor quality.

Customer satisfaction increased due to timely & good quality castings supply.

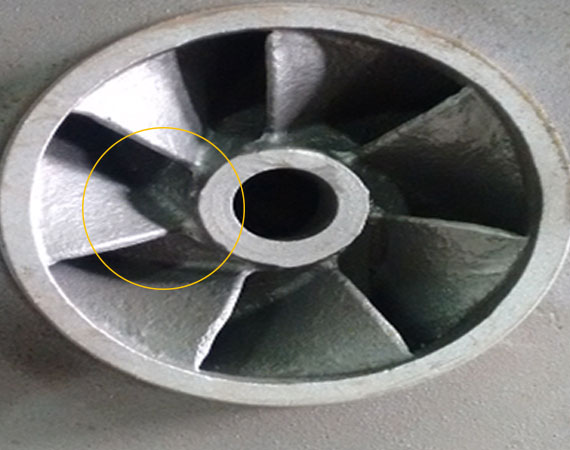

Veining Defect :

Heavy veining at inner veins.

Unable to remove in fettling process.

Result is rejection of casting.

After Veinseal™ Solution :

Veining reduced by 100% in single trial.

Major saving in cost of poor quality.

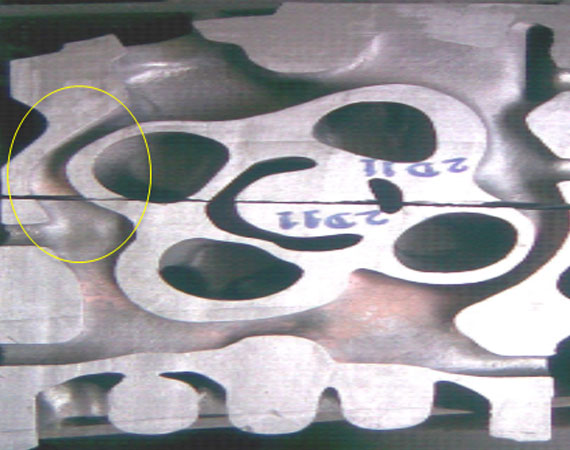

Veining Defect :

Heavy veining/fusion at intricate core areas.

Unable to remove in fettling process.

Result is rejection of casting.

Unable to complete dispatch plan.

After Veinseal™ Solution :

Veining/fusion reduced.

Major saving in cost of poor quality.

Customer satisfaction increased due to timely & good quality castings supply.

Our Offerings

Our Exclusive Products and Solutions

- Complete solutions to problems related to shell sand.

- Exclusive RCS grades for critical applications such as water jacket cores, cylinder head cores, highly critical hydraulic applications.

- Lower expansion RCS grades to overcome veining defects.

- Anti-veining compound from Prince Minerals, LLC, USA, for various applications in coldbox, no-bake, shell cores to eliminate veining/fusion defects.

- Special RCS grades based on Chromite Sand, Ceramic Sand, High Strength Low Density Sands.

- Sand for 3D printing.

Get in Touch

Get in touch with us for Customized Sand Grade Solution

Call us on

+91 9922930766

Email us

mktg@samarthsand.com

Why Choose Us

The premium quality of Samarth Coated Sand is a result of

Thorough Understanding Of Casting Defects And Their Root Causes

Expertise Developed On Sand Processing Including Thermal Sand Reclamation.

Premium Quality Raw Material Sourcing.

Manufacturing Facility Having Flexibility To Cater To Varying Customer Requirements.

Comprehensive QA And R & D Facilities Including Product Performance Testing In Our Own Foundry.

Special Purpose Sands Developed To Cater To Your Unique Requirements

Get in Touch

Get in touch with us for Customized Sand Grade Solution

Call us on

+91 9922930766

Email us

mktg@samarthsand.com